Mori Seiki NMH 5000 DCG machining centre

AB-2507-865

Poststraße 117, 73054 Eislingen/Fils, Deutschland

Year of manufacture: 2011

Net weight: 21,000 kg

Overall dimensions: 6.1 m × 6 m × 3.3 m

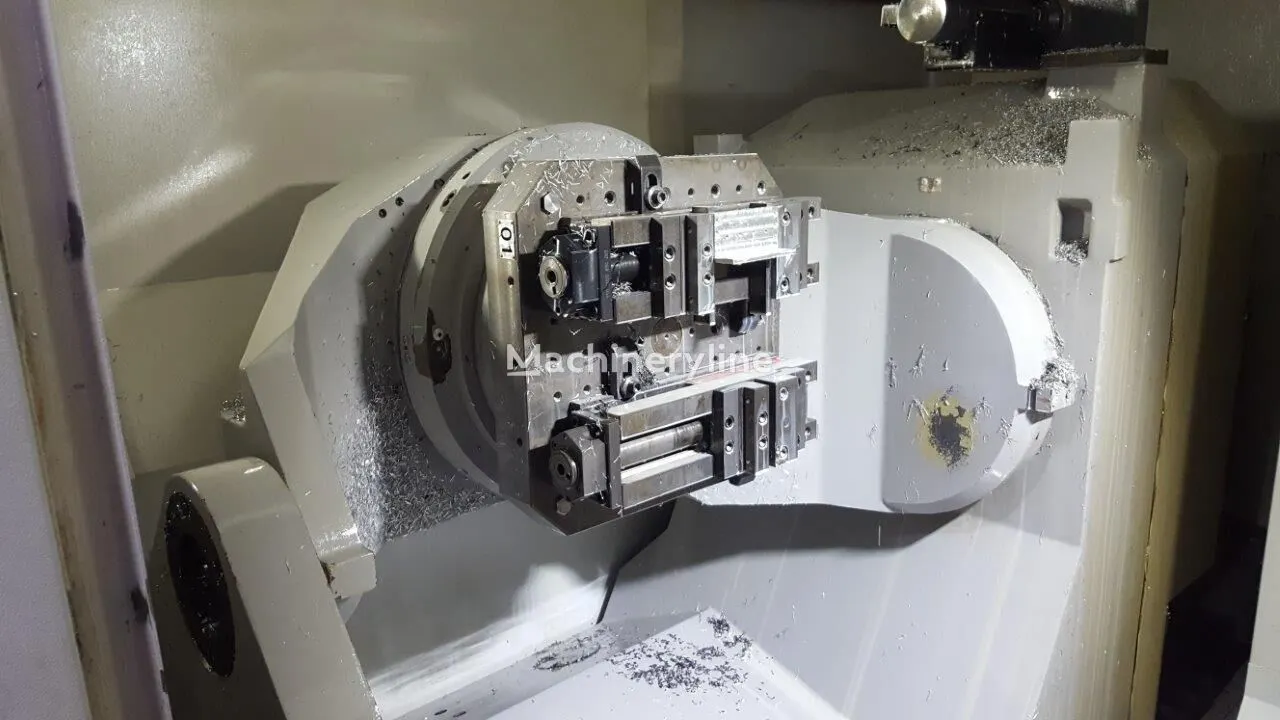

Horizontal 5-axis machining center,

equipped with full A- and B-axis,

IKZ high-pressure cooling through the spindle at 50 bar (Frascara),

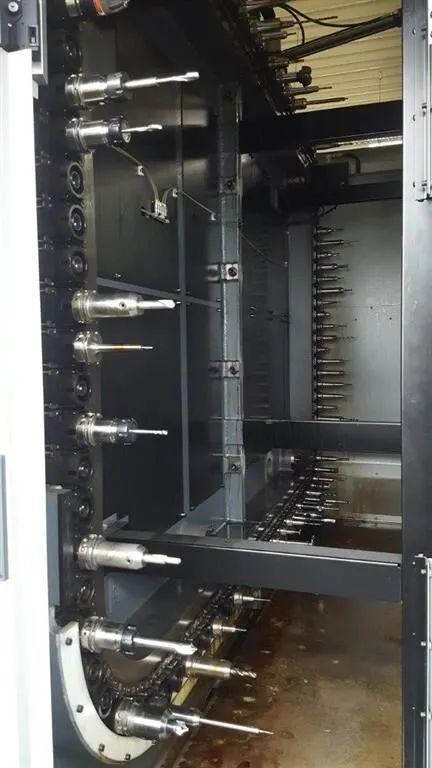

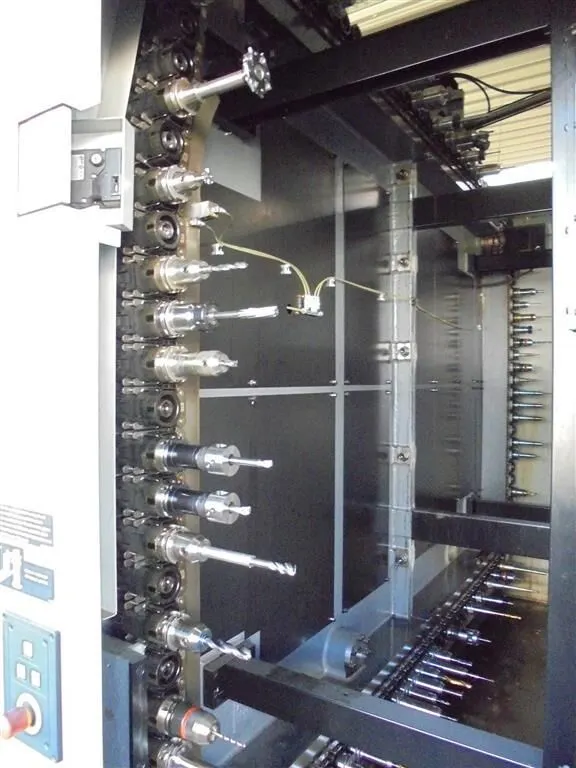

120-tool magazine HSK-A 63,

chip conveyor,

tool break and length measurement,

Renishaw spindle probe.

Machine is in excellent condition with low operating hours.

Machine type: Universal machining center

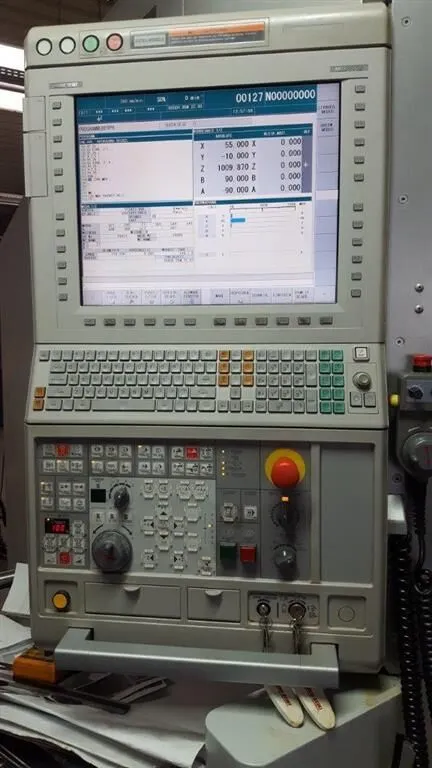

Control type: CNC

Location: Germany

Country of origin: Japan

Delivery time: Immediate

Shipping terms: EXW (Incoterms 2010) free loaded truck

X-axis travel: 730 mm

Y-axis travel: 850 mm

Z-axis travel: 1100 mm

Control system: MSX 711 MAPPS IV

Spindle power: 22 / 18.5 kW

Spindle speed: 12,000 rpm

Tool magazine: 120 HSK-A 63

Max. tool diameter: 70 mm

Max. tool diameter with free magazine slots: 140 mm

Max. tool length: 480 mm

Max. tool weight: 12 kg

Rapid traverse x/y/z: 50,000 mm/min

A-axis (5th axis) swivel table: +30° to -120°

Rapid traverse B-axis (rotary table): 50 rpm

Rapid traverse A-axis (swivel axis): 20 rpm

Dual pallet changer: 2 × 500 × 500 mm

Max. workpiece weight: 500 kg

Workpiece installation height: 700 mm

Max. workpiece diameter on pallets: 700 mm

Total power requirement: 63 kVA

Number of coordinate systems: 300

MAPPS tool management system: GB

Storage capacity: 1 MB

Program registers: 1000

Internal coolant supply 50 bar with filter: Frascara