Ads On

Industrial machines & components > Metalworking machinery > Grinding machines

Filters

Reset filterZum Verkauf steht eine Schleifmaschine.

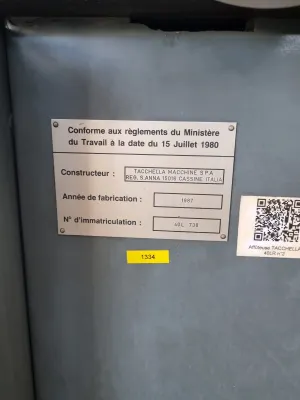

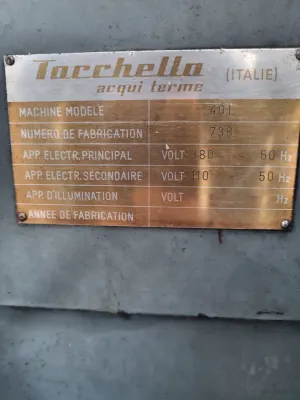

Model: 40L

Hersteller: Tacchella Macchine

Baujahr: 1987

Messenhäuser Str. 42, Rödermark-Urberach, Deutschland

Es wird ein Metabo Doppelschleifbock, Doppelschleifmaschine des Typs Ds D 9201 mit Untergestell verkauft.

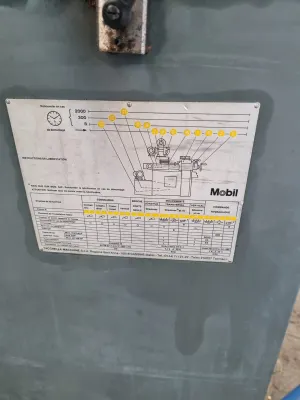

Auf den Bildern sieht man weitere Informationen.

Poststraße 117, 73054 Eislingen/Fils, Deutschland

Year of manufacture: 1987

Net weight: 3,500 kg

Condition: Used

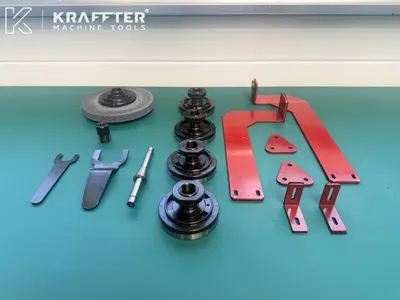

- Fully mechanically overhauled, CNC-controlled precision cylindrical grinding machine

- Extensive accessories

- Cooling system

- Electronic handwheel

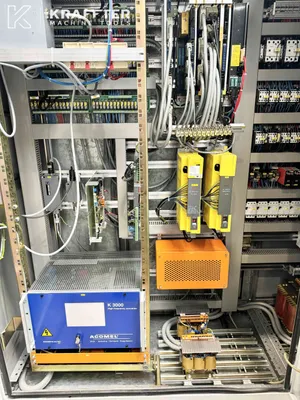

- Separate control cabinet

- Safety emergency stop

Machine type: Universal cylindrical grinding machine

Control type: CNC

Location: Eislingen main warehouse

Country of origin: Switzerland

Delivery time: By arrangement

Shipping terms: Ex Warehouse

Grinding diameter: 350 mm

Grinding length: 1000 mm

Center height: 175 mm

Workpiece weight: 120 kg

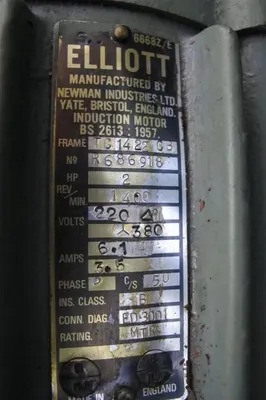

Drive power: 5.5 kW

Maximum speed: 25,000 rpm

Control system: FMS 5-88

Feldstraße 27, 32108 Bad Salzuflen-Schötmar, Deutschland

Kurzbeschreibung

Die MVM ZX ist eine professionelle Langmesserschleifmaschine zum präzisen Schärfen von geraden Messern. Erhältlich in zwei Versionen mit 1000 mm oder 1230 mm nutzbarer Schleiflänge. Geeignet für eine breite Palette an Messern, z. B. Hobelmesser, Holzhackmesser sowie Recycling- und Schneidmühlenmesser.

Serienausstattung / Hauptmerkmale

- Gusseiserner Tank / Maschinenbett

- Schleifscheibenmotor 1,5 kW (2 PS)

- Automatische Schleifscheibenzustellung (komfortabler, reproduzierbarer Schleifprozess)

- Schwenkbarer Schleifkopf

- Führungen mit auswechselbaren Bändern aus gehärtetem und geschliffenem Stahl

- Mechanischer Messerspanntisch 0° bis 90° drehbar

- Kühlmittelpumpe (Nassschliff)

- Kettenantrieb für den Schleifschlitten

- Stufenanschläge zum gleichzeitigen Schleifen von bis zu 4 Hobelmessern

Optionen / Zubehör (auf Wunsch)

- Untergestell

- Magnettisch 0° bis 90° drehbar

- Stufenlose Schlittengeschwindigkeit 1–11 m/min

- Anschlaglineal

- Externer Kühlmitteltank mit Pumpe

- Schleifscheibenmotor 2,2 kW (3 PS)

- Einstellbare Schleiflänge

- Spannaufnahme für Tersa, Centrofix, Terminus, Kanefusa, Sinus oder Weinig Messer

- Magnettisch für Hartmetall-Werkzeuge

Typische Einsatzbereiche

- Kunststoffrecycling / Schneidmühlen (Messer schärfen, Standzeiten verlängern)

- Holzindustrie (Hobelmesser, Hackmesser)

- Service-Werkstätten / Instandhaltung / Werkzeugschleiferei

95355 Presseck, Bayern, Deutschland

Preis netto 2000 + steuer Steuer 19 % = 2380.- brutto

mit Btriebsanleitung

gerne übersende ich Alle Bilder der Maschine

Feldstraße 27, 32108 Bad Salzuflen-Schötmar, Deutschland

Kurzbeschreibung

Die MVM BM 650 / BM 850 ist eine kompakte, vielseitige Messerschleifmaschine zum professionellen Schärfen von geraden Messern in der Holz- und Recyclingtechnik. Mit passendem Zubehör lassen sich verschiedene Messer- und Werkzeugtypen präzise schleifen – ideal für Hobelmesser, Hackermesser sowie Schneidmühlen-/Granulator-Messer.

Schleifbare Messer / Werkzeuge (mit Zubehör)

- Hobelmesser

- kleine Hackermesser

- kleine Granulator-/Schneidmühlenmesser

- Einwegmesser (z. B. Tersa, Sinus, Weinig und ähnliche Systeme)

- Hartmetall-Wendeschneidplatten / Widia-Inserts

Hauptmerkmale (Serienausstattung)

- Gusseiserner Tank / Maschinenbett

- Automatische Schleifscheibenzustellung (Downfeed) mit automatischem Stopp auf eingestellter Höhe

- Schwenk-/Kippbarer Schleifkopf (u. a. für Hohlschliff/konkave Flächen)

- Führungen mit auswechselbaren, gehärteten und geschliffenen Stahlbändern

- Mechanischer Messerspanntisch/Spannfutter 0° bis 90° drehbar

- Kühlmittelpumpe (Nassschliff)

- Kettenantrieb für den Schleifschlitten

- Stufenanschläge zum gleichzeitigen Schleifen von 4 überlappenden Hobelmessern

Optionen / Zubehör (auf Wunsch, je nach Ausführung)

- Untergestell

- Magnettisch 0° bis 90° drehbar

- Stufenlose Schlittengeschwindigkeit 1–11 m/min oder feste 5,5 bzw. 11 m/min

- Anschlaglineal

- Externer Kühlmitteltank mit Pumpe

- 0° Bezugspunkt am Tisch

- Einstellbare Schleiflänge

- Spannvorrichtung für Ledermesser

- Magnettisch für Hartmetall-Werkzeuge

- Spannaufnahme für Tersa, Centrofix, Terminus, Kanefusa, Sinus oder Weinig Messer

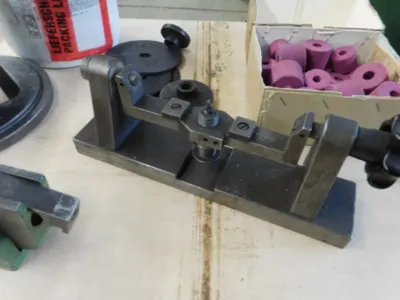

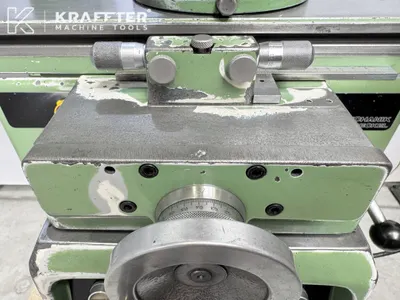

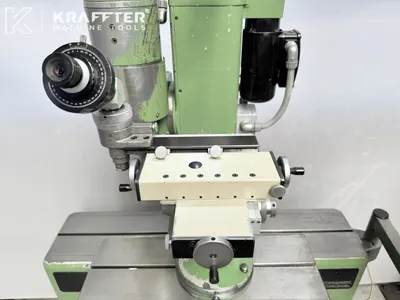

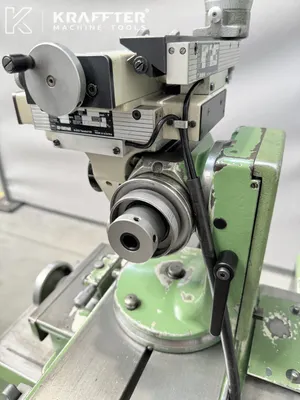

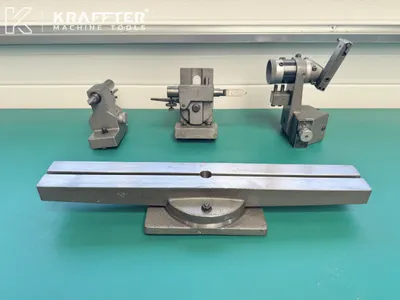

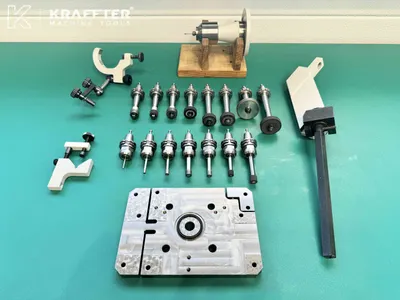

Tool grinding machine DECKEL S11

TECHNICAL CHARACTERISTICS:

Grinding wheel diameter: 125 [mm]

Workpiece spindle nose: ISO 40

Paper filtration unit: No

Supply voltage: 400 [V]

Total power required: 2 [kVA]

Dimensions: 1100 x 800 x 1760

Weight: 520 [Kg]

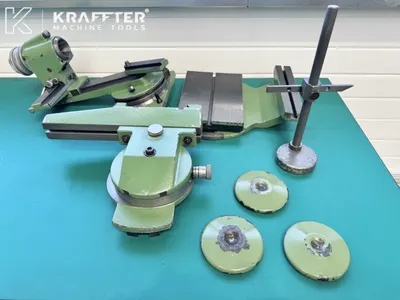

EQUIPMENT INCLUDED:

x1 universal index head - Part N°: 255X0X

x10 dividing inserts for universal index head

x1 tailstock with transverse adjustment - Part N°: 2621000

x1 tailstock with vertical adjustment - Part N°: 2624000

x1 swivel bracket assembly - Part N°: 2626000

x1 universal wheel dresser - Part N°: 2628000

x1 universal setting gauge - Part N°: 2570000

x1 spiral and relief grinding attachment - Part N°: 2580000

x1 relief grinding slide - Part N°: 2673000

x1 machine vice - Part N°: 2635000

x1 opto-electronic measuring unit with miscroscope - Part N°: 2650012

x2 digital readouts RSF-Elektronik

x1 radius grinding attachment - Part N°: 2601X00

x1 LED lamp

x3 feet pads

Machine visible under power in our premises by appointment.

Price on request, loading on truck included.

Possibility of shipping Worldwide.

The information on this page has been obtained by the best of our ability. Therefore, its accuracy can not be guaranteed.

Machine for sharpening tools, milling cutters, taps, and drills.

Similar to brands such as Blohm, Elb, Ewag, Favretto, Fenix, Ger, Jones & Shipman, Jung, Karstens, NUMAFFUT, Okamoto, Okuma, Saacke, SMP, Studer, Vollmer, Walter.

Also see cylindrical or surface grinders, lathes, machining centers, and milling machines.

St. Daniel 81a, 9635 Dellach, Österreich

Präzise Werkzeugschleifmaschine für vielseitige Anwendungen in der Metallbearbeitung

Die Hispano Suiza Albula ist eine robuste Werkzeugschleifmaschine mit großem Verfahrweg und hoher Drehzahlflexibilität. Ideal geeignet für das Nachschleifen von Werkzeugen und präzise Schleifarbeiten im Maschinenbau.

Technische Daten:

– Spitzenhöhe: 140 mm

– Tischfläche: 150 × 1.050 mm

– Längsweg (manuell): 600 mm

– Querweg: 230 mm

– Höhenverstellung: 250 mm

– 2 Motordrehzahlen: 1.500 / 3.000 U/min

– 6 Schleifspindeldrehzahlen: 2.000 – 6.000 U/min

– Max. Schleifscheibendurchmesser: 250 mm

Besonderheiten:

– Ideal zum Nachschleifen und Feinschleifen von Werkzeugen

– Große Präzision und feinfühlig einstellbare Achsen

– Kompakte, stabile Bauweise

– Sofort einsatzbereit

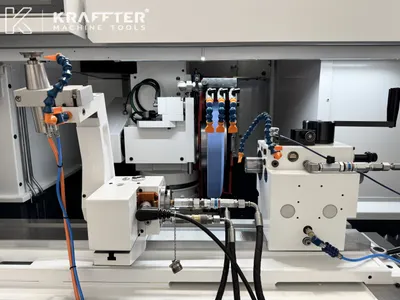

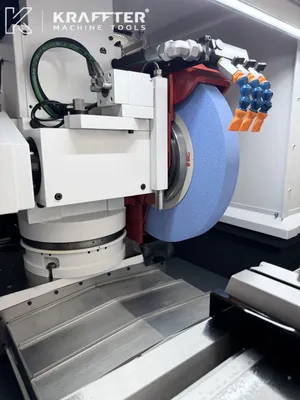

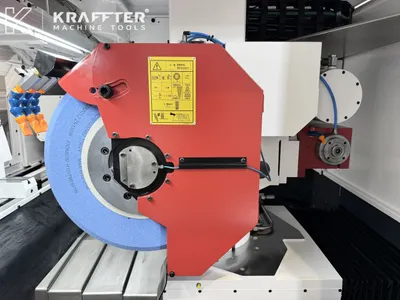

CNC Cylindrical grinder STUDER S33

TECHNICAL CHARACTERISTICS:

Year of manufacturing: 2006

CNC control: FANUC 21i-TB

Software installed: StuderGrind

Centre distance: 1000 [mm]

Height of centers: 175

Stroke X axis: 285 [mm]

Min. Stroke speed X axis: 0.001 [mm/min]

Max. Stroke speed X axis: 5000 [mm/min]

Resolution X axis: 0.0001 [mm]

Stroke Z axis: 1150 [mm]

Min. Stroke speed Z axis: 0.001 [mm/min]

Max. Stroke speed Z axis: 10000 [mm/min]

Resolution Z axis: 0.0001 [mm]

B axis swivelling stroke: -15 [°] / +195 [°]

B axis indexing precision: Hirth 1 [°]

Automatic B axis: Yes

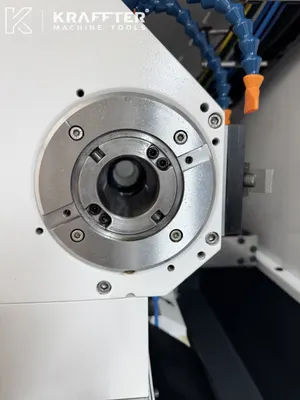

Workpiece spindle nose: MT5

Workpiece spindle min. speed: 1 [rpm]

Workpiece spindle max. speed: 1500 [rpm]

Max. part weight in part holder headstock between centres: 120 [Kg]

Type of attachment tailstock: MT3

Tailstock quill stroke: 35 [mm]

Tailstock quill diameter: 50 [mm]

Tailstock fine adjustment: +/- 40 [mm]

Supply voltage: 400 [V]

Total power required: 20 [kVA]

Weight: 5700 [Kg]

INCLUDED EQUIPMENT:

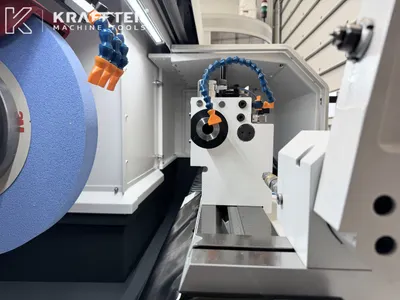

x1 internal grinding spindle type 102540B – speed: 40,000 [rpm]

x1 swiveling dressing attachment

x1 rotating dressing device DR.KAISER type C42 DC 058 – speed: 25,000 [rpm] – 0.17 [kW]

x1 frequency converter MAAS type SPS-9250

x1 pneumatic tailstock lift

x1 pneumatic upper-table lift

x1 longitudinal slide with rotary table - swiveling up to 8.5 [°]

x1 automatic B-axis turret wheelhead – Hirth gearing 1 [°]

x1 C-axis for thread and form grinding

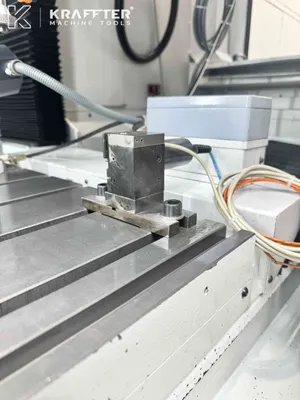

x1 workpiece probe MOVOMATIC C25

x1 contact control device DITTEL SENSITRON 2

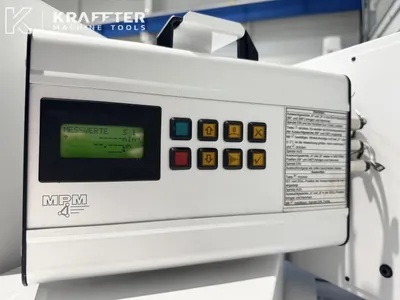

x1 semi-automatic wheel balancing device MPM type 3.BMT100M

x1 paper filtration unit STREULI AG

x1 mist extraction unit AFS Air Filter Systeme

x1 electrical cabinet air conditioner

x3 external grinding wheel flanges

x2 lifting blocks

x1 axis bracket (for transportation of the machine)

x1 set of operating manuals (French, English, and German)

Machine visible under power in our premises by appointment.

Price on request, loading on truck included.

Possibility of shipping Worldwide.

The information on this page has been obtained by the best of our ability. Therefore, its accuracy can not be guaranteed.

Similar machine to the brands Okamoto, ELB, GER, Tacchella, Karstens, Jones & Shipman, Jung, Favretto, Blohm, Studer. Also see surface grinder, lathe, machining center, milling machine.

Poststraße 117, 73054 Eislingen/Fils, Deutschland

Year of Manufacture: 1980

Net Weight: 3,500 kg

Condition: Used

Machine Type: Horizontal Surface Grinding Machine

Control Type: CNC

Location: Eislingen Main Warehouse

Country of Origin: Germany

Availability: Immediately

Shipping Terms: Ex Works

Grinding Length: 600 mm

Grinding Width: 300 mm

Workpiece Height: 375 mm

Spindle Speed: 1000 – 3000 rpm

Grinding Wheel Dimensions: 300 × 50 × 76.2 mm

Grinding Spindle Power: 2.8 – 8.4 kW

Features:

- 3D-controlled profile dresser

- ELB-CNC Unicon control with integrated electronic handwheel

- Display and analog spindle load indicator

- Stepless adjustable cross feed

- Coolant system with magnetic roll separator

- Full enclosure

- Separate control cabinet

- Additional grinding wheel with flange

An der Hühnerhecke 8A, 63755 Alzenau, Deutschland

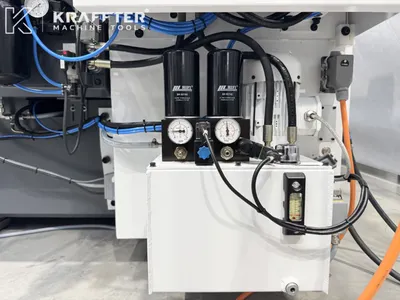

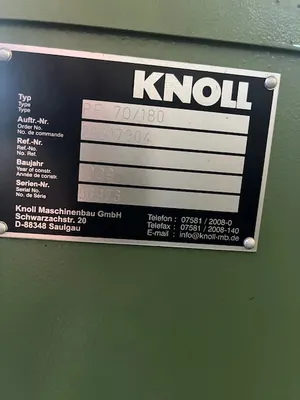

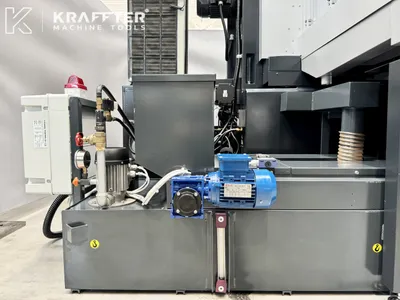

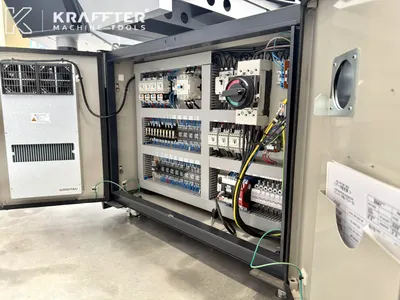

KNOLL Schwerkraftbandfilter Typ PF70/180

Baujahr 1999, neuwertig

Ausstattung:

- Vliesmangelschalter

- Vliesrolle im Gehäuse integriert

- Füllstandsmesstechnik

- Gehäusegröße: 1200 x 720 x 1000 mm

Preis: € 1.400,-

CNC Surface grinder OKAMOTO ACC42SA-IQ

TECHNICAL CHARACTERISTICS:

Year of manufacturing: 2017

Colour touchscreen: Yes

Maximum grinding lenght x width: 400 x 200 [mm]

Stroke X axis (table movement): 510 [mm]

Min. Stroke speed X axis: 100 [mm/min]

Max. Stroke speed X axis: 20000 [mm/min]

Z axis travel (transverse movement): 220 [mm]

Min. distance spindle nose / table: 22.5 [mm]

Max. distance spindle nose / table: 357.5 [mm]

Max. load on table: 120 [Kg]

Grinding wheel min. speed: 1000 [rpm]

Grinding wheel max. speed: 3600 [rpm]

Grinding spindle motor power: 2.2 [kW]

Max. diameter grinding wheel: 205 [mm]

Max. grinding wheel width: 16 [mm]

Min. grinding wheel width: 6 [mm]

Grinding wheel bore: 31.75 [mm]

Number of running hours: 59 [h]

Supply voltage: 400 [V]

Total power required: 11 [kVA]

Weight : 2100 [Kg]

INCLUDED EQUIPMENT:

x1 150 [L] coolant tank FB1/R with papertape filtration unit FB1

x1 BRAILLON electro-permanent magnetic chuck type EPEFINE 2

x1 BRAILLON magnetic chuck remote control, microprocessor-based, type T10

x5 grinding wheel flanges

x1 oil chiller

x1 transformer

x2 service keys

x1 balancing shaft

x1 set of axis-brackets for transport

STANDARD CONVERSATIONAL PROGRAMMING MODE:

Straight and angular dressing (standard)

Surface grinding, multiple plunge grinding, and face grinding (standard)

INCLUDED ISO PROFILING:

Wheel profiling

Contour machining of workpiece

Full functionality for V-shape and freeform programming on the grinding wheel, and ISO contouring on the workpiece.

Precise positioning integrated: +/- 1 [μm]

Machine visible under power in our premises by appointment.

Price on request, loading on truck included.

Possibility of shipping Worldwide.

The information on this page has been obtained by the best of our ability. Therefore, its accuracy can not be guaranteed.

Similar machine to brands like Jones & Shipman, Jung, Favretto, Blohm, Studer. Also see cylindrical grinder, lathe, machining center, milling machine.

Distance between centers: 650 mm

ID / OD

2-axis SONY digital read out

Coolant tank

Poststraße 117, 73054 Eislingen/Fils, Deutschland

Net Weight: 400 kg

Overall Dimensions: 0.65 m × 0.7 m × 1.7 m

Condition: Used

Machine Type: Precision Cup Grinding Machine

Control Type: Conventional

Location: Eislingen Main Warehouse

Country of Origin: Germany

Availability: Immediately

Shipping Terms: Ex Works

Workpiece Length: 310 mm

Workpiece Width: 160 mm

Workpiece Height: 150 mm

Spindle Speed: 3150 rpm

Spindle Overhang: 120 mm

Grinding Height (max): 350 mm

Features:

- Original Kugel Mueller cast iron base with accessory drawer

- Lower storage compartment with door

- Diamond cup wheel Ø 90 mm

- Original extraction hood for direct mounting above spindle

- Height-adjustable grinding head with vernier handwheel fine adjustment and hydraulic rapid adjustment

- Minimum spindle nose to table distance: 205 mm

- Maximum spindle nose to table distance: 400 mm

- Two additional sets of V-belt pulleys for different speeds

- Four cup wheels, two brand new

- Two grinding wheel balancing spindles

- Good condition

Poststraße 117, 73054 Eislingen/Fils, Deutschland

Year of Manufacture: 1971

Net Weight: 1,000 kg

Condition: Used

Machine Type: Surface Grinding Machine

Control Type: Conventional

Location: Eislingen

Country of Origin: Germany

Availability: Immediately

Shipping Terms: Ex Works, free loading onto truck

Grinding Length: 530 mm

Grinding Width: 225 mm

Workpiece Height: 470 mm

Distance Table to Bottom Spindle: 530 mm

Spindle Speeds: 2140 & 2850 rpm

Magnetic Chuck (electric): 390 × 150 mm

Table Size: 500 × 200 mm

Table Speed: 0.6 – 30 m/min

T-Slots: 3 × 12.5 mm

Cross Feed: 0 – 10 mm/stroke

Grinding Wheel Dimensions: 255 × 25 × 75 mm

Total Power Requirement: approx. 1.4 kW

Space Requirement (approx.): 1.55 × 1.20 × 1.72 m (W×D×H)

Features:

- Manual dressing device

CNC JIG GRINDING MACHINE HAUSER S40-400

TECHNICAL CHARACTERISTICS :

Stroke X axis: 650 [mm]

Max. Stroke speed X axis: 4000 [mm/min]

Working feed X axis: 0 - 1800 [mm/min]

Stroke Y axis: 450 [mm]

Working feed Y axis: 0 - 1800 [mm/min]

Stroke Z axis: 130 [mm]

Min. Stroke speed Z axis: 0.5 [mm/min]

Max. Stroke speed Z axis: 12000 [mm/min]

Stroke frequency Z axis: max. 4 [Hz]

Stroke W axis: 500 [mm]

Planetary speed C axis: 5 - 250 [rpm]

Max. Stroke speed W axis: 800 [mm/min]

Stroke U axis (radial feed): 5.5 [mm]

Distance between columns: 750 [mm]

Table length: 770 [mm]

Table width: 630 [mm]

Clearance between grinding motor and table: 585 [mm]

Max. load on table: 500 [Kg]

Supply voltage: 400 [V]

Weight: 4550 [Kg]

ADDITIONAL INFORMATION :

x1 HI-CUT pack including:

-work area protection

-exhaust system with electrostatic air filter

-fire protection system (to be assessed by a qualified body)

-HTG-RWS-60 automatic belt filter cooling unit

x1 MSS (Multi-Sensoric System) tool detection device

x1 CBN dressing unit with HF drive for automatic dressing of CBN grinding wheels (ceramic bond and synthetic resin)

x1 T16 grinding turbine - speed: 160,000 rpm - reference: 164225

x1 turbine support with filter for use with T10 and T16 turbines - reference: 166497

x1 60S-TC grinding motor, speed 9000 - 60000 [rpm], for SK20 collets - part number: 208450

x1 intermediate plate for aligning motors and urbines - reference: 192940

x1 centring watch holder for grinding motor rotor - reference: 191790

x15 wheel holder cleats

x1 cable for grinding motor

Various tools

Full documentation

Machine visible under power in our premises by appointment.

Price on request, loading on truck included.

Possibility of shipping Worldwide.

The information on this page has been obtained by the best of our ability. Therefore, its accuracy can not be guaranteed.

The HAUSER S40-400 is a high-precision CNC coordinate grinding machine. This machine excels in tight tolerance environments such as contouring applications in the aerospace, automotive and medical industries. Thanks to its robust design and advanced capabilities, the HAUSER S40-400 is comparable to machines from well-known brands such as Moore. It can be integrated into workshops comprising Mägerle (Magerle), Studer, Moore, Kellenberger, Okamoto, Jones & Shipman, and ELB machines.

In addition to its performance, the HAUSER S40-400 integrates perfectly into workshops equipped with lathes, machining centres or CNC milling machines, offering a complete solution for high-precision grinding and machining of complex parts.